| 2018-2019 TEI4M Assembly Tasks |

![]() 40. THE 4-WIRE DC FAN. Researching and developing this project has been extremely rewarding and it is a superb context for assembling and reviewing much of the engineering content we have explored over the past two and a half years. Furthermore, this project requires the use of all three timers available on the Arduino!

40. THE 4-WIRE DC FAN. Researching and developing this project has been extremely rewarding and it is a superb context for assembling and reviewing much of the engineering content we have explored over the past two and a half years. Furthermore, this project requires the use of all three timers available on the Arduino!

Keeping electrical components at their optimum temperature is key to their performance. It's not surprising then that Intel, one of the world's leading chip maker, offers manufacturer's precise specifications for DC cooling fans in their document, 4-Wire PWM-Controlled Fans.

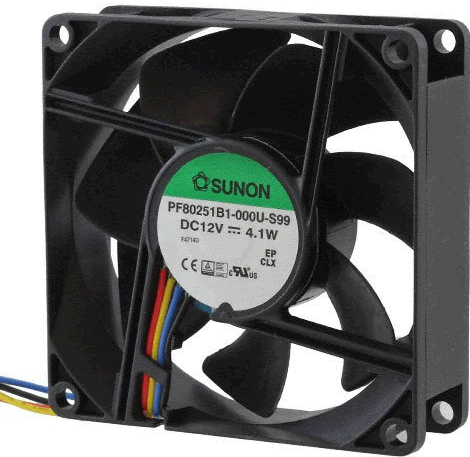

The specific model chosen for our investigation is Sunon's 4-wire 12VDC ball bearing fan. This device offers a number of features that can be explored under elementary and advanced microcontroller operation. Additionally, a sentence from the Intel specification caught my eye. In its overview it claims, "The expectation is a 4 wire PWM controlled fan, when properly implemented, will be significantly quieter than a similar 3 wire fan". I'd like us to confirm this.

PART A. GETTING ACQUAINTED WITH THIS FAN

PART B. IMPLEMENTATION. Apart from your ISPs, this DC Fan Project is the marquee entry in your DER. In future employment interviews, this is the project you should draw your recruiter's attention to as it speaks to an extremely high level of competency and facility.

You've earned the right to implement reports through your own eyes so I'm giving you the freedom to organize your summary as you see fit. On the other hand, I still remain in judgment of the depth of your Reporting so take your time and make sure you include EVERYTHING. This is big.

For this followup DER entry from Part A, you need to take your readers through a comprehensive discussion of the hardware and software support required to exploit the characteristics described in Part A.

Your report will provide text, graphic, and video content detailing the power, speed (ADC/PWM), and sense (TACH/Input Capture) features of the 4-wire cooling fan.

On the software side, incorporate a discussion of the Assembly language control and manipulation of the AVR peripherals (Timers and ADC).

I'll leave the rest to you. Additional material remains below from the 2017-2018 version of the project. Feel free to incorporate some/most of it.

The web has a great deal of instructional content for interfacing 2- and 3-wire fans. For 4-wire fans there is far less and some if it is inefficiently designed or simply wrong.

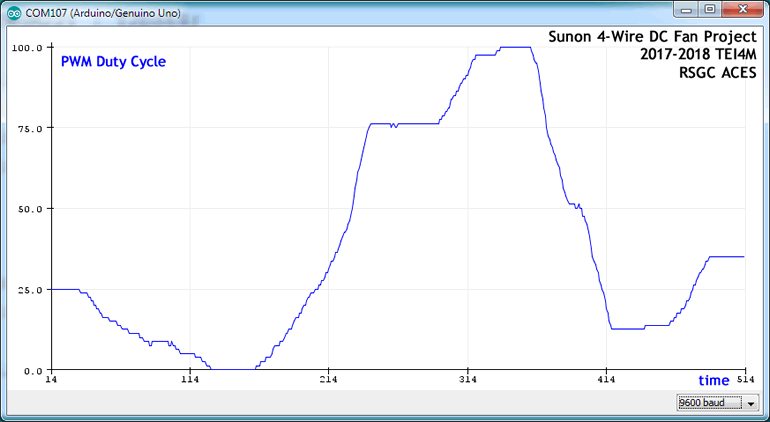

PART C. PWM DESIGN. PWM signal design (modulation) requires consideration of two characteristics: frequency and duty cycle. Our (fun) challenge is to configure an AVR timer to provide a PWM signal to match the optimal requirements outlined in fan's datasheet. Whereas the frequency of the signal remains constant, the duty cycle (speed) should be variable (in this stage, we'll hard code the changes to the duty cycle. In the next stage we'll consider external control (manual or sensor) over the duty cycle). Finally, as you develop your solution, remember, the best (most efficient) strategy places as much, if not all, the burden on the hardware that can perform in the background.

PART C. PWM DESIGN. PWM signal design (modulation) requires consideration of two characteristics: frequency and duty cycle. Our (fun) challenge is to configure an AVR timer to provide a PWM signal to match the optimal requirements outlined in fan's datasheet. Whereas the frequency of the signal remains constant, the duty cycle (speed) should be variable (in this stage, we'll hard code the changes to the duty cycle. In the next stage we'll consider external control (manual or sensor) over the duty cycle). Finally, as you develop your solution, remember, the best (most efficient) strategy places as much, if not all, the burden on the hardware that can perform in the background.

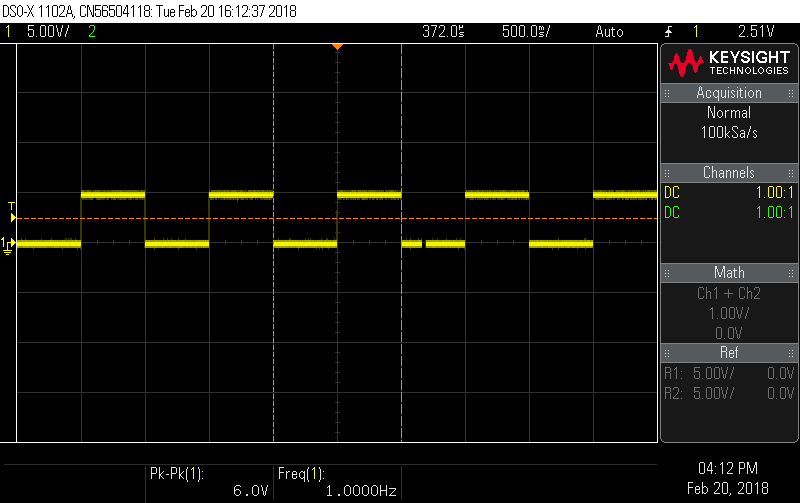

T. Morland (RSGC '18) developed a working solution after class Wednesday and offers us this scope trace of his assembly implementation ...

PART C Task.

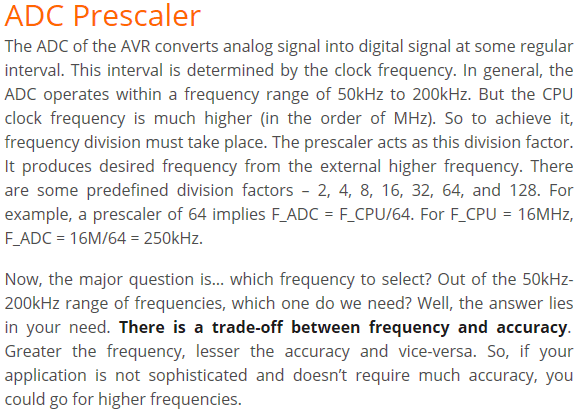

PART D. Speed Control (ADC). We've reached the stage in this project where the speed of the fan (duty cycle) is turned over to the operator. For this, we need to explore low-level register manipulation of the AVR's ADC unit.

PART D. Speed Control (ADC). We've reached the stage in this project where the speed of the fan (duty cycle) is turned over to the operator. For this, we need to explore low-level register manipulation of the AVR's ADC unit.

PART D Task.

PART E. SENSE (FEEDBACK, TACHOMETRY, YELLOW) WIRE (Demodulation of PART C's PWM).

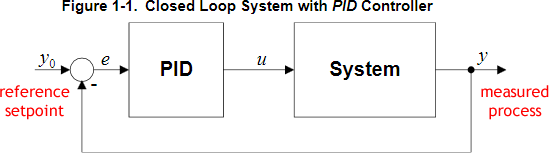

OPEN loop systems (no feedback) are undesirable as the user has no idea if the process is functioning as designed.

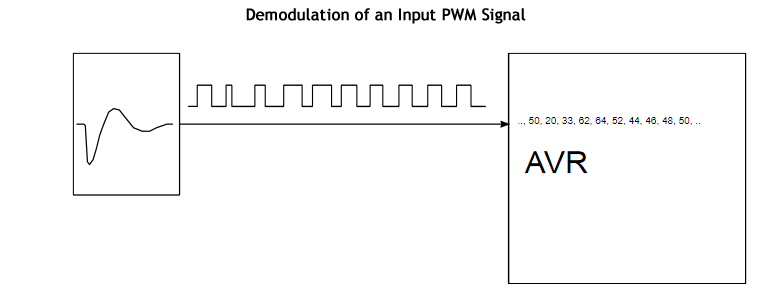

CLOSED loop devices such as our 4-wire fan offer a means of monitoring and adjusting our input PWM by sensing the speed of rotation and placing this signal on the fourth (yellow) wire. This variable PWM signal can be captured and demodulated by our microcontroller, analyzed and the data used to adjust the input PWM as necessary to ensure the fan is maintaining a desired performance. Note. All sorts of information can be carried by a PWM signal. An image from the datasheet you are about to read suggests how the duty cycle of a PWM signal could be used to carry ASCII data. Inspiring stuff.

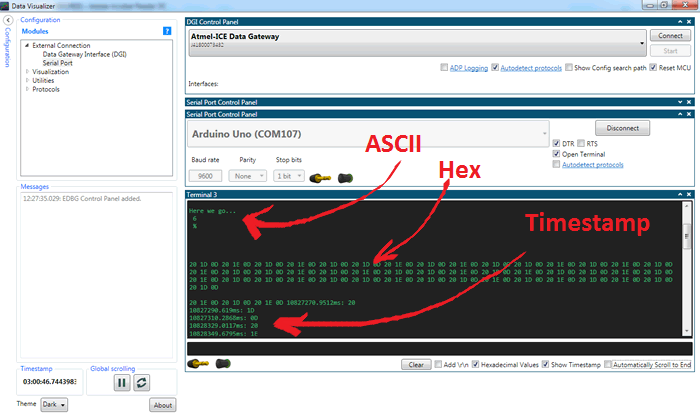

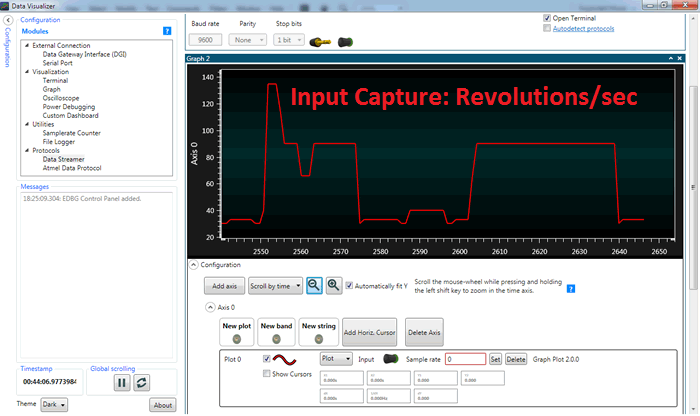

The 328P's Timer1 facilitates the capture of the yellow wire's PWM signal through it's ICP1 function (mapped to Arduino's digital pin 8). Demodulation of this signal will expose the fan's actual RPM. Furthermore, through Atmel Studio's Data Visualizer feature we can explore AVR's Serial Communication feature and plot both the theoretical and actual RPM. This sets us up well for the final stage of this project, PART F: PID.

PART E. Task (TACH Wire Demodulation)

PART E. Task (TACH Wire Demodulation)

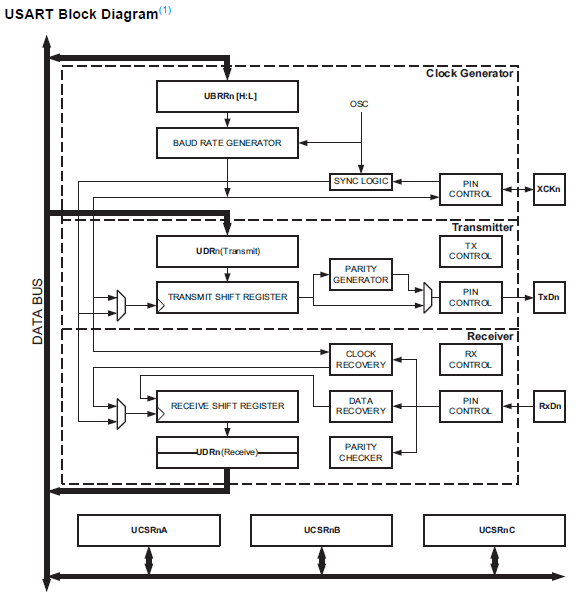

PART F. Serial Communication (USART: Universal Synchronous/Asynchronous serial Receive and Transmit) After all the groundwork previously laid we're now in the enviable position of acquiring data from our system and placing it into serial data stream for external retrieval.

PART F. Serial Communication (USART: Universal Synchronous/Asynchronous serial Receive and Transmit) After all the groundwork previously laid we're now in the enviable position of acquiring data from our system and placing it into serial data stream for external retrieval.

In this stage we're going to confirm and display as text, the value of OC2B and number of falling edges the tach wire is yielding per second.

Just as the Serial Monitor and Serial Plotter are available tools within the Arduino IDE, Atmel Studio offer a far more comprehensive utility, the Data Visualizer, that does a great deal more. To fully exploit its capabilities we must learn to navigate the AVR's USART subsystem.

Reference 1: Serial Communication is discussed in Chapter 20 of the ATmega328P datasheet

Reference 2: Microchip's Data Visualizer Home Page

Reference 3: Microchip's Data Visualizer Users' Guide

PART F. Task.

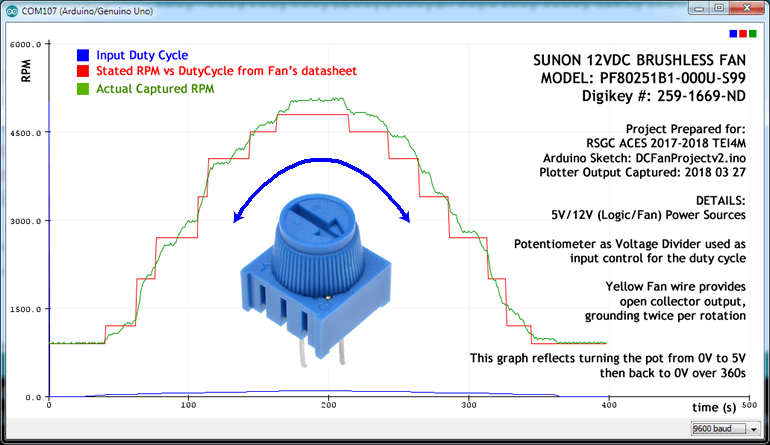

PART G. Graphic Data Visualization. In this stage we wish to generate a graphic plot comparing the theoretical RPM to the empirical RPM obtained through feedback, setting the stage for the final leg of this [epic 8-part] marathon: PID in which we expect to the expected and actual plots to merge. A plot of the Duty Cycle, Theoretical RPM and Empirical RPM are displayed over a FULL range of input duty cycles provided by a potentiometer was undertaken weeks ago in the high-level Arduino IDE and visualized by it's Serial Plotter utility over 1 s intervals. in this stage we'll see to what extent we can produce a similar visualization through AVR assembly exploiting Atmel Studio's Data Visualizer.

| Arduino Serial Plotter | Atmel Studio 6 Data Visualizer |

|---|---|

|

|

PART G. Task.

PART H. PID. You are well-aware that simply supplying a device with a required signal is not sufficient to GUARANTEE required performance. To achieve this you must create a closed loop that continually measures the process output (actual device performance) and dynamically adjusts the setpoint signal by reducing or eliminating the variance (error-e).

PID Principle 1: Introduction: PID Controller Design

PID Principle 2: PID Controller on AVR Devices

PID Principle 3: Detailed PID Library Discussion

PID Principle 4: The PID Controller (Nuts&Bolts Magazine)

Application 1: Arduino: DC Motor Control Position Control using PID

Part H. Task.

AVR TIMERS

38.

38. ![]() Timer1. Fast PWM Mode 15. In this exercise you are asked to develop standalone assembly code that will result in the the horn of your HXT500 standard servo motor sweeping through its 180ˆ of rotation, continuously.

Timer1. Fast PWM Mode 15. In this exercise you are asked to develop standalone assembly code that will result in the the horn of your HXT500 standard servo motor sweeping through its 180ˆ of rotation, continuously.

Task.

37. ![]() USART Debugging Utility. In this exercise you are asked to develop a utility that can be used to debug your assembly code by dumping the contents of SRAM the Serial Monitor.

USART Debugging Utility. In this exercise you are asked to develop a utility that can be used to debug your assembly code by dumping the contents of SRAM the Serial Monitor.

Task.

36.

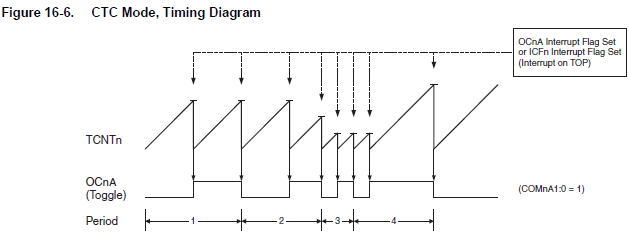

36. ![]() Timer1. Clear Timer on Compare Match. Mode 4 (Output CTC) and Mode 12 (Input CTC) result in clearing the TCNT1H:L register pair when it matches the preset OCRnA/B H:L register pair (Mode 4) or the ICRnA/B register pair (Mode 12). The latter can be exploited for recording timestamps for input events. Interrupts can be configured for both OC1A/B. The attached pins (9 and 10) can be manipulated (cleared, set or toggled) using the COM1A/B bits in TCCR1A to shape the resulting PWM Signal. This is somewhat easier to use than setting the start count less than the TCNTn resolution an climbing all the way to the overflow.

Timer1. Clear Timer on Compare Match. Mode 4 (Output CTC) and Mode 12 (Input CTC) result in clearing the TCNT1H:L register pair when it matches the preset OCRnA/B H:L register pair (Mode 4) or the ICRnA/B register pair (Mode 12). The latter can be exploited for recording timestamps for input events. Interrupts can be configured for both OC1A/B. The attached pins (9 and 10) can be manipulated (cleared, set or toggled) using the COM1A/B bits in TCCR1A to shape the resulting PWM Signal. This is somewhat easier to use than setting the start count less than the TCNTn resolution an climbing all the way to the overflow.

35. ![]() Timer1. Normal Mode with Output Compare (Software and Hardware Interrupts). In addition to a strictly hardware output response to the occurrence of a Compare event, on A and/or B, one can add a software response as well.

Timer1. Normal Mode with Output Compare (Software and Hardware Interrupts). In addition to a strictly hardware output response to the occurrence of a Compare event, on A and/or B, one can add a software response as well.

Task.

.global TIMER1_COMPA_vect

TIMER1_COMPA_vect:

...

reti

34.

34. ![]() Timer1. Normal Mode with Output Compare (Hardware Intr). A closer look at the pin mapping of the Arduino reveals 6 digital pins with alternate functionality labelled OCnX (pins 3, 5, 6, 9, 10, & 11).

Timer1. Normal Mode with Output Compare (Hardware Intr). A closer look at the pin mapping of the Arduino reveals 6 digital pins with alternate functionality labelled OCnX (pins 3, 5, 6, 9, 10, & 11).

These pins can be configured to change their state (cleared, set or toggled) when the timer counter register pair (TCNT1H:TCNT1L) matches the value preloaded into the Output Compare Register pair (OCR1A/BH:OCR1A/BL). Since this functionality is achieved primarily at the hardware level, it has the potential to offer high, asynchronous, efficiency. On the other hand, the constant comparison of the TCNT1H:L register with the OCR1AH:L and/or OCR1BH:L register pairs places such a burden on CPU performance, even the 328p datasheet does not recommend its use (p. 146).

One final note. As attractive as it is to forgo the need for an explicit software interrupt, the issue of clearing the OCF1A and/or OCF1B flags in the TIFR1 regsiter remains a problem. Since polling the flag and clearing it by writing a one to the bit is one solution, but the preferred soltion for us is to simply include dummy ISRs for the OC1Aaddr and/or OC1Baddr interrupts addresses in the interrupt jump table so the flags are cleared automatically.

Task.

33b.

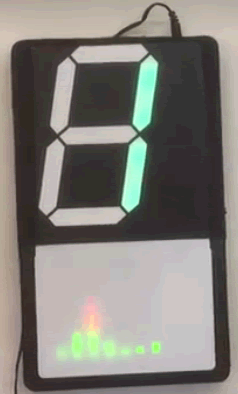

33b. ![]() Light It Up! (This should be fun:) Each of you has been given a Piezo Buzzer with which we'll attempt to crank up the audio in the DES confirming each of the 7 frequency bands of the MSGEQ7 used in Ethan's Equalizer at the front of the room.

Light It Up! (This should be fun:) Each of you has been given a Piezo Buzzer with which we'll attempt to crank up the audio in the DES confirming each of the 7 frequency bands of the MSGEQ7 used in Ethan's Equalizer at the front of the room.

33a.

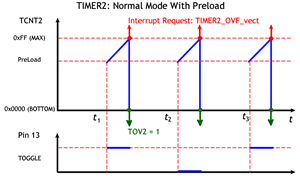

33a. ![]() Sound: Timer2 Normal Mode with PreLoad. In the previous exercise you simply let the Timer's counter run freely, restarting at 0x00 on the overflow. In this exercise you are asked to undertake an audio exploration of Timer2's Overflow Interrupt (in Normal Mode) while manipulating the TCNT2 register.

Sound: Timer2 Normal Mode with PreLoad. In the previous exercise you simply let the Timer's counter run freely, restarting at 0x00 on the overflow. In this exercise you are asked to undertake an audio exploration of Timer2's Overflow Interrupt (in Normal Mode) while manipulating the TCNT2 register.

In this exercise you are asked to toggle Pin 13 with Timer2 Interrupt Overflows so as to recreate the provided audio file.

Task.

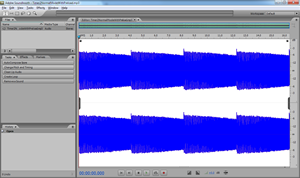

the volume remains relatively stable while the frequency (pitch) increases. The mono waveform, recorded in stereo, is shown below right as it appear in Adobe's SoundBooth.

the volume remains relatively stable while the frequency (pitch) increases. The mono waveform, recorded in stereo, is shown below right as it appear in Adobe's SoundBooth.

32. ![]() Timers as Audio Frequency Generators. AnalogWrite PWM and the tone() Function.

Timers as Audio Frequency Generators. AnalogWrite PWM and the tone() Function.

AnalogWrite PWM

We have put the 6 Arduino PWM pins to good use in the past to affect the duty cycle of our signals but not the frequency. The frequency remained beyond the scope of the analogWrite(pin,dutyCycle) function.

We have put the 6 Arduino PWM pins to good use in the past to affect the duty cycle of our signals but not the frequency. The frequency remained beyond the scope of the analogWrite(pin,dutyCycle) function.

uint8_t pwmPin = 11;

void setup(){

pinMode(pwmPin,OUTPUT);

}

void loop() {

for (int i=0; i<255; i++) {

analogWrite(pwmPin,i);

delay(30);

}

}

You will recall that the parameter to the analogWrite() function affects the duty cycle (mark/space ratio). Frequency and volume are the two primary audio characteristics you'll experience. Which of the two are affectd by the changing parameter? Does this make sense?tone(pin, frequency, duration) Function

31.

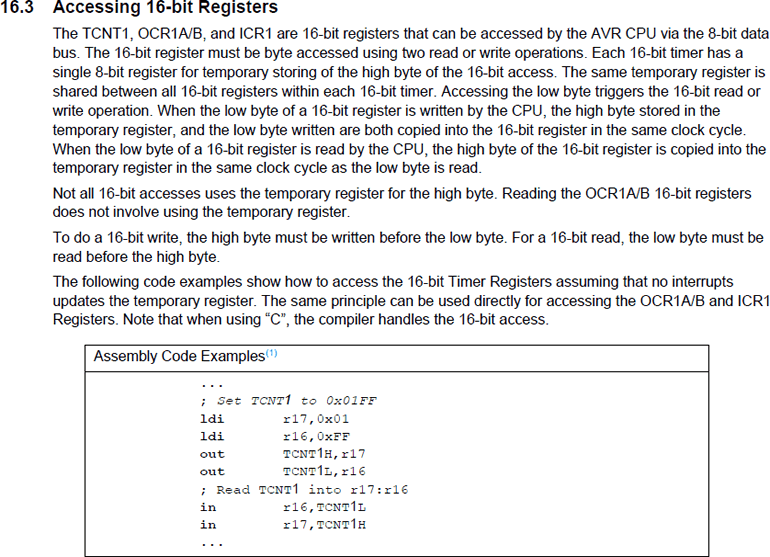

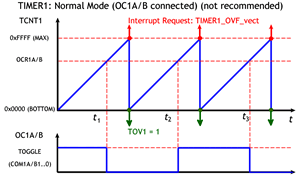

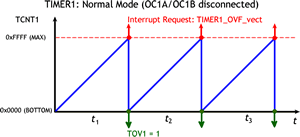

31. ![]() Timer1. Normal Mode. The absolute simplest of 16 different Timer1 modes results in the system clock incrementing its 16-bit register pair TCNT1H:TCNT1L with every cystal oscillation. At 16 MHz (~`2^24`), the count will fill the register pair (`2^16`), ~244.14 times per second and trigger an interrupt if properly configured in code. When the count reaches the top an interrupt overflow (TIMER1_OVF_vect) is generated and the count continues from 0x0000 like an odometer whether you service the request or not. Setting the TOIE1 bit in the TIMSK1 register, together with the enabling of the global interrupt flag in the SREG allows your code to respond to the request.

Timer1. Normal Mode. The absolute simplest of 16 different Timer1 modes results in the system clock incrementing its 16-bit register pair TCNT1H:TCNT1L with every cystal oscillation. At 16 MHz (~`2^24`), the count will fill the register pair (`2^16`), ~244.14 times per second and trigger an interrupt if properly configured in code. When the count reaches the top an interrupt overflow (TIMER1_OVF_vect) is generated and the count continues from 0x0000 like an odometer whether you service the request or not. Setting the TOIE1 bit in the TIMSK1 register, together with the enabling of the global interrupt flag in the SREG allows your code to respond to the request.

Review the document, T1NormalOVFISR.docx. In it you'll find an Arduino Register-level implementation of a Timer1 Normal Mode Overflow Interrupt Routine to ease you into the Assembly-level register implemenations required in the Task(s) below. This example employs an ISR to toggle an LED on PB5 at rate of ~244 ovf/s, leading to frequency of 122 Hz.

Task 1.

Task 2. (Prescale)

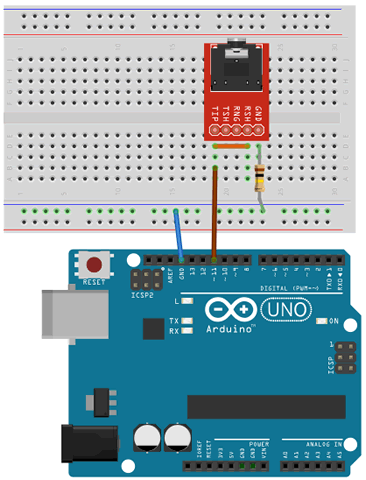

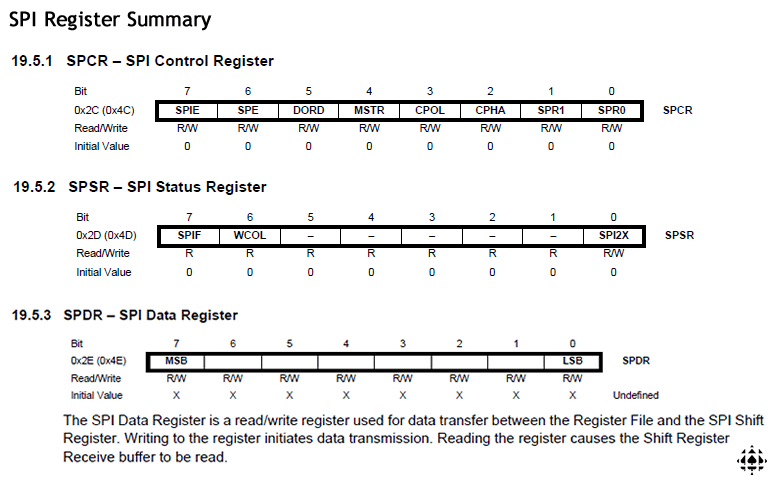

![]() 31. SPI: Serial Programming Interface. One of the most established communication protocols within the embedded systems device field is the three-wire, full duplex SPI (AVR151).

31. SPI: Serial Programming Interface. One of the most established communication protocols within the embedded systems device field is the three-wire, full duplex SPI (AVR151).

Note 1. Since the standard is loosely interpreted, you are encouraged to check a device's datsheet for any variations the manufacturer has adopted.

A fairly reliable starting point is to assume there is one master device that exchanges data bits, serially, with multiple slave devices under strict sequencing of clock pulses provided by the master.

Note 2. An additional wire is required for each additional slave device. A specific slave is selected by the master to communicate with by pulling its respective Slave Select (SS) line low prior to the exchange and reutned to high upon completion.

The common ISP (AVR910) activity used to flash code to your Arduino is one such example of the SPI schema.

Full details of the SPI peripheral can be found in Chapter 19 of the ATmega328p's datasheet and supported by resources linked from our course page as well as countless online tutorials. A summary of the three dedicated SPI Registers appears below. It can be seen that, if properly configured, Interrupt Jump Address 18 (SPI_STC_vect) is triggered upon the Completion of a Serial Transmission from the master. The task below demonstrates an example of this behaviour.

THE STACK (Stack Pointer: SP) ( __SP_H__ : __SP_L__ )

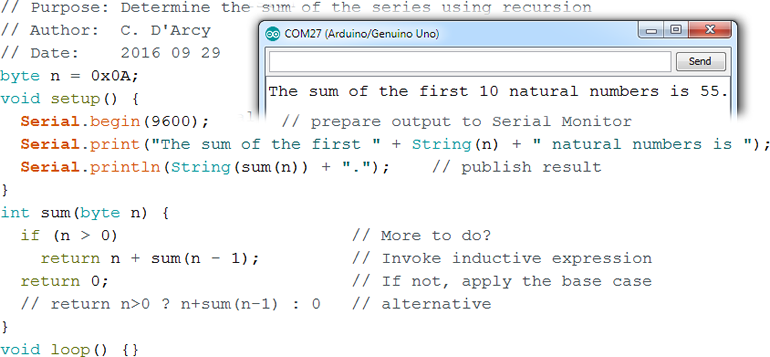

30. ![]() Sum of a Series 2. Recursion is a programming strategy in which a function calls itself to solve a simpler version of the problem until the process reaches a trivial base case. Review the sketch below.

Sum of a Series 2. Recursion is a programming strategy in which a function calls itself to solve a simpler version of the problem until the process reaches a trivial base case. Review the sketch below.

In this exercise you develop an assembly language equivalent as a means to understanding the uses of the STACK to pass values and address between callers and receivers.

![]() Note. On second thought, I don't recommend doing this exercise. Few people in their right mind would attempt this. It took me two days to figure this out. Here's the Excel spreadsheet I used to work out the logic if you're interested.

Note. On second thought, I don't recommend doing this exercise. Few people in their right mind would attempt this. It took me two days to figure this out. Here's the Excel spreadsheet I used to work out the logic if you're interested.

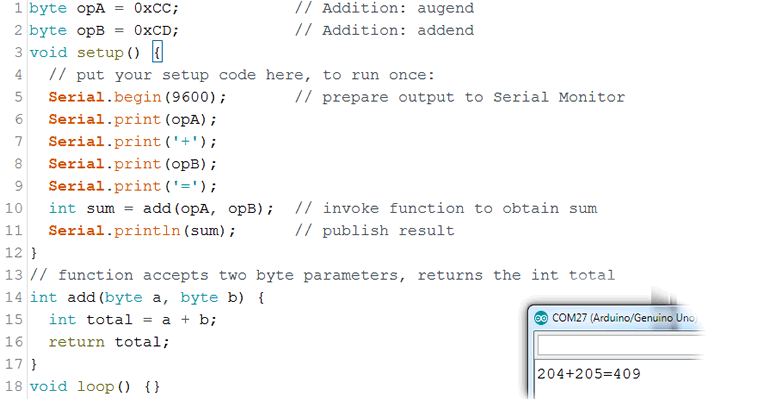

29. Subroutine: Add. The sketch below presents a somewhat formal, high-level solution to adding two bytes with the support of a function (Assembly: Subroutine). What we're interested in, in this exercise, are the details of the passing of the input parameters to the function and the receipt of the return parameter. With this knowledge, you can undertake an assembly language version of this code.

The graphic to the right is intended to show the relationship between the Caller code, the Subroutine and the role played by the Stack in ensuring the communication between the two takes place accurately. I'll be better able to explain how it all works when we're together.

Task. Develop a sketch entitled AddSubroutine.ino that mimics the high-level code above. Incorporate all the best assembly language practices we have highlighted so far.

28. Swapping 3. (push, pop) Declare and initialize two global variables to different values. Implement assembly language instructions to accomplish the same result as Swapping 1 but makes use of the Stack instead.

26. Matrix Position. For a final look at input polling, develop MatrixAnimation.ino. The assembly code monitors FOUR push buttons for position data before uploading column and row data to two shift registers connected to your 788BS.

26. Matrix Position. For a final look at input polling, develop MatrixAnimation.ino. The assembly code monitors FOUR push buttons for position data before uploading column and row data to two shift registers connected to your 788BS.

The result is that a single LED dot moves about on your matrix as demonstrated in the adjacent animation.

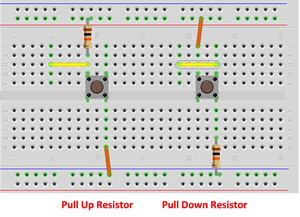

25b. [17/18] Bargraph Position. Create the AS7 Assembler project, BargraphPosition. Grab a bargraph and wire six consecutive LEDs to PortB (PB0-PB5) of your Arduino. Wire two push buttons to external interrupts 0 and 1 using a hardware debounce strategy that uses (internal or external) pullup resistors.

25b. [17/18] Bargraph Position. Create the AS7 Assembler project, BargraphPosition. Grab a bargraph and wire six consecutive LEDs to PortB (PB0-PB5) of your Arduino. Wire two push buttons to external interrupts 0 and 1 using a hardware debounce strategy that uses (internal or external) pullup resistors.

implements ISRs for both of the external interrupts that are called on the falling edge of the respective button activity. INT0 should result in the active LED position moving to the left and INT1 resulting in the active LED position moving one position to the right. In both cases implement a wraparound. Your assembly code can start with any LED of the six turned on.

25a. Bargraph Position. Using your Arduino, develop the assembly project BargraphPosition.ino that polls TWO push buttons to control left and right movement of a bar on your bargraph. A single shift register is to be employed to provide the byte data to the bargraph.

25a. Bargraph Position. Using your Arduino, develop the assembly project BargraphPosition.ino that polls TWO push buttons to control left and right movement of a bar on your bargraph. A single shift register is to be employed to provide the byte data to the bargraph.

24. Multiple Inputs. In this exercise you are asked to attach three buttons to PORTD pins, one for the red, green, and blue results on an RGB LED. The three buttons are also wired through OR logic (a three-input IC would be great or two cascaded two-input gates) to a single PORTD pin that is polled continuously. Once a state change has been detected, poll the three buttons and light the respective LED for 2s before repeating the exercise.

24. Multiple Inputs. In this exercise you are asked to attach three buttons to PORTD pins, one for the red, green, and blue results on an RGB LED. The three buttons are also wired through OR logic (a three-input IC would be great or two cascaded two-input gates) to a single PORTD pin that is polled continuously. Once a state change has been detected, poll the three buttons and light the respective LED for 2s before repeating the exercise.

23. Input Polling (in,out,sbi,cbi,sbrc,sbrs,sbic,sbis).

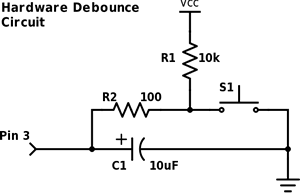

We'll get to interrupts later in the course, but for now you are asked to attach a hardware-debounced button to a port pin of your ATtiny85 and monitor it for a state change. Once recognized, turn an LED on for 3s before repeating the exercise. AVR Delay Loop Calculator.

Note: There are three I/O registers associated with each Port. i.e. DDRB, PORTB, and PINB

23. Input Polling (in,out,sbi,cbi,sbrc,sbrs,sbic,sbis).

We'll get to interrupts later in the course, but for now you are asked to attach a hardware-debounced button to a port pin of your ATtiny85 and monitor it for a state change. Once recognized, turn an LED on for 3s before repeating the exercise. AVR Delay Loop Calculator.

Note: There are three I/O registers associated with each Port. i.e. DDRB, PORTB, and PINB

22.

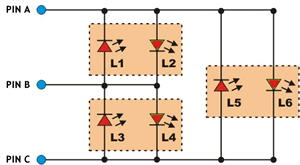

22. ![]() Charlieplexing. The use of shift registers is a hardware solution employed to extend the reach of logic beyond the number of I/O pins on your microcontroller. If the goal is to simply drive more LEDs than the number of microcontroller pins available, a purely software solution is Charlieplexing. The key to successful implementation of this technique is the three-state logic capability of the microcontroller's digital I/O pins meaning the pins can be in one of three states: Output (H)IGH, Output (L)OW and Input (Z) . Placing an I/O pin in the Input (Z) or high impedance state effectively disconnects the pin from the LED network. As can be imagined, given n digital I/O pins, a network of n2-n LEDs can be driven. This is simply the permutation defined by,

Charlieplexing. The use of shift registers is a hardware solution employed to extend the reach of logic beyond the number of I/O pins on your microcontroller. If the goal is to simply drive more LEDs than the number of microcontroller pins available, a purely software solution is Charlieplexing. The key to successful implementation of this technique is the three-state logic capability of the microcontroller's digital I/O pins meaning the pins can be in one of three states: Output (H)IGH, Output (L)OW and Input (Z) . Placing an I/O pin in the Input (Z) or high impedance state effectively disconnects the pin from the LED network. As can be imagined, given n digital I/O pins, a network of n2-n LEDs can be driven. This is simply the permutation defined by,

`P(n,2)=(n!)/((n-2)!)=n(n-1)=n^2-n`

Task.

| PIN A | PIN B | PIN C | |

|---|---|---|---|

| L1 | L | H | Z |

| L2 | H | L | Z |

| L3 | Z | L | H |

| L4 | Z | H | L |

| L5 | L | Z | H |

| L6 | H | Z | L |

Research Links.

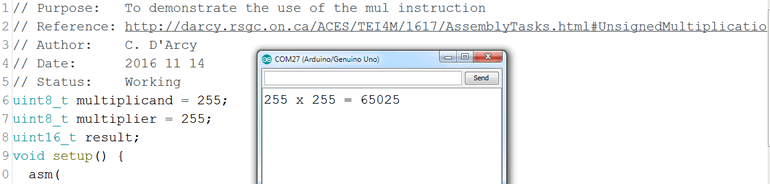

21. Multiplication (mul, muls, mulsu).The AVR Instruction Set breaks down the multiplication of 8-bit operands into three cases: mul (unsigned×unsigned), muls (signed×signed), and mulsu (signed×unsigned). Regardless of which registers contain the operands, the 16-bit product is always placed in the r1:r0 register pair. You are asked to develop an example of each.

Note 1. The avr-gcc compiler supports numerous integer types. Use the correct one in each context below.

Note 2. It appears that the Serial library uses r0 and r1 for its own purposes and prevents the assembly code from obtaining correct results. Delay the use of the library until after the results have been obtained.

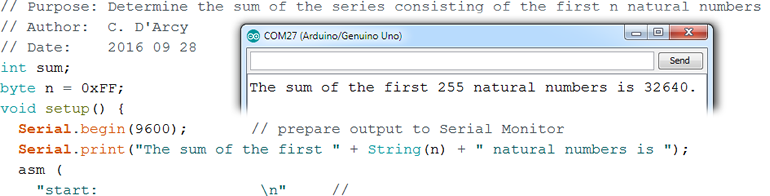

20. Sum of a Series 1. The sum of the first n natural numbers can be expressed as,

`sum_(i=1)^n i=(n(n+1))/2`

Create a sketch entitled SumSeries.ino that begins in a manner similar to the capture below and uses assembly instructions to accumulate the sum. The value of n can be limited to a byte (uint8_t) but the sum must accommodate a uint16_t total. The output appears in the inset.

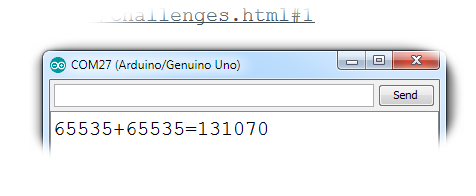

19. Addition of uint16_ts. (add, adc, eor). Create a sketch entitled AddInts. Declare and initialize two global variables, opA and opB, of type uint16_t and a global variable sum of type uint32_t. Implement assembly language instructions to add the two operands and store the result in sum. Add Serial functions to confirm the result.

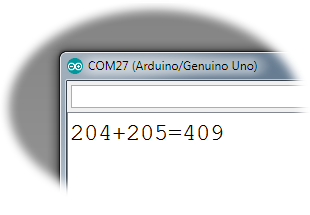

18. Addition of uint8_ts. (add, adc). Create a sketch entitled AddBytes. Declare and initialize two global variables, opA and opB, of type uint8_t and a global variable sum of type uint16_t. Implement assembly language instructions to add the two operands and store the result in sum. Add Serial functions to confirm the result as in,

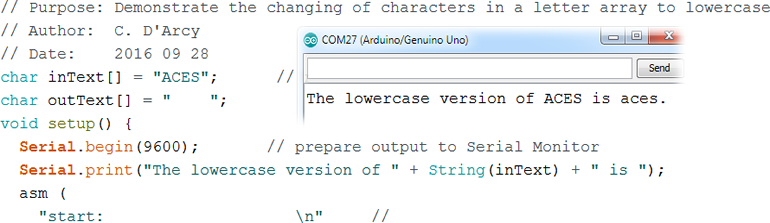

17. ToLowercase 2: char[]. This exercise extends the previous one by asking you to convert all the letters in a char array to their lowercase equivalent.

Develop the sketch, ToLowerCaseCharArray.ino that begins as shown below and yields the output in the inset.

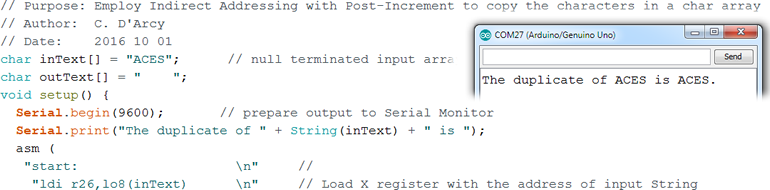

16. ![]() ArrayCopy : char[]. (ld, st, lo8(), hi8()) In this exercise you will employ Indirect Addressing with Post-Increment to duplicate the characters in an input array.

ArrayCopy : char[]. (ld, st, lo8(), hi8()) In this exercise you will employ Indirect Addressing with Post-Increment to duplicate the characters in an input array.

Task.

LOGICAL

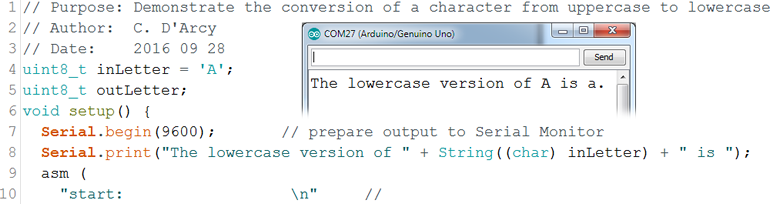

15. ToLowerCase 1: char. You are likely aware that the ASCII Table defines the numeric value of the lowercase letters to be 32 more than their uppercase equivalents. Develop the sketch ToLowercaseChar.ino that employs assembly language instructions to obtain the value of a global variable of type char that defines an uppercase letter and through an appropriate mask, uses a logic instruction to convert it to its lowercase equivalent. Display the result to confirm.

14. OR Mask (or,ori). To ensure specific bits of a register are set while preserving the state of other bits, the or or ori instruction can be employed with the use of a mask. Consider the byte mask 0x0F. Applying this mask to a register with the ori instruction, will result in bits 0 through 3 being set while bits 4 through 7 remain unaffected. Develop the sketch ORIMask.ino that employs assembly language instructions to set the even-numbered bits, while leaving the odd-numbered bits unaffected. You will accomplish this though the design of an appropriate mask applied with the ori instruction. Display the results to confirm.

14. OR Mask (or,ori). To ensure specific bits of a register are set while preserving the state of other bits, the or or ori instruction can be employed with the use of a mask. Consider the byte mask 0x0F. Applying this mask to a register with the ori instruction, will result in bits 0 through 3 being set while bits 4 through 7 remain unaffected. Develop the sketch ORIMask.ino that employs assembly language instructions to set the even-numbered bits, while leaving the odd-numbered bits unaffected. You will accomplish this though the design of an appropriate mask applied with the ori instruction. Display the results to confirm.

13. AND Mask (and,andi). Individual bits of a register can be set or cleared through the use of a 'mask' applied with the and instruction. Consider the byte mask 0x01. Applying this mask to a register with the and instruction, will clear bits 1 through 7 and preserve the value of bit 0 in the register. Develop the sketch ANDMask.ino that employs assembly language instructions to clear the upper nibble of a byte, preserving the original contents of the lower nibble. You will accomplish this through the design of an appropriate mask applied with the andi instruction. Display the results to confirm.

FOUNDATIONS

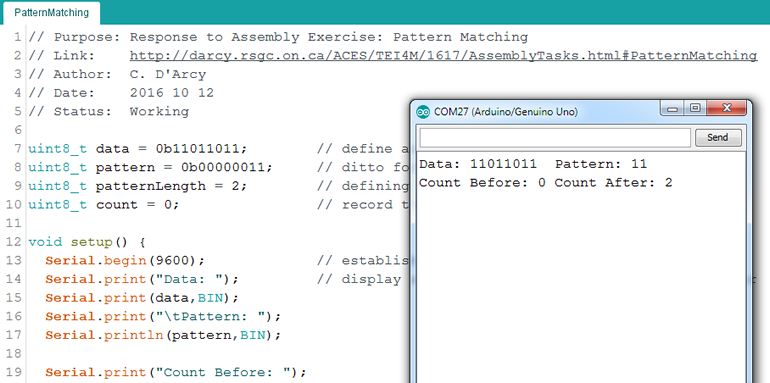

12. Pattern Matching (and, cp, lsr, mov). Searching for a particular sequence of bits within a longer bit sequence is common task. In this exercise you are asked to count the number of occurrences of a bit pattern within a data byte. In the graphic below the number of occurrences of the bit pattern 11 within the byte 11011011 is determined to be 2. One might think it is 3 but, for this exercise, the search starts at bit 0 and advances through the target byte by an amount equal to the number of bits in the sought after pattern.

Task. Create a sketch entitled PatternMatching.ino, and start it off as shown below. Complete the assembly statements that lead to the results as shown in the inset.

11. Parity. In the early days of computing, communication between computers was particularly vulnerable to noise (static) on the lines resulting in errors (dropped bits) in transmission. A strategy developed to reduce the number of errors was for the transmitting and receiving devices to first agree on whether bytes transferred would ALWAYS contain an EVEN or ODD number of bits. A dropped bit could be detected if the number of bits received did not reflect the agreed-upon protocol. Since the basic ASCII table only required 7 bits of information, the eighth bit (sometimes referred to as the parity bit) would be SET or CLEARED depending on the protocol.

11. Parity. In the early days of computing, communication between computers was particularly vulnerable to noise (static) on the lines resulting in errors (dropped bits) in transmission. A strategy developed to reduce the number of errors was for the transmitting and receiving devices to first agree on whether bytes transferred would ALWAYS contain an EVEN or ODD number of bits. A dropped bit could be detected if the number of bits received did not reflect the agreed-upon protocol. Since the basic ASCII table only required 7 bits of information, the eighth bit (sometimes referred to as the parity bit) would be SET or CLEARED depending on the protocol.

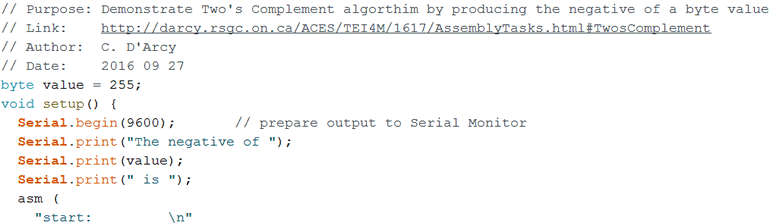

10. Two's Complement. In deciding on a strategy for storing negative numbers (given there's no minus sign), computer scientists decided the highest priority was to ensure a number and it's negative added up to 0. The strategy they came up with for determining the negative of a number, that all computers today have adopted, is known as the Two's Complement algorithm. Look up the neg instruction and it declares it to be Two's Complement right in the title!

Tasks (4).

1. Research the Two's Complement algorithm. What is the One's Complement? Apply the Two's Complement to a binary byte value using pencil and paper. What would result if you applied it twice? Try it.

2. Develop the sketch NegativeByte.ino that uses the neg assembly instruction to produce the negative of a global byte variable. Display to confirm. Observations?

3. Develop the sketch, TwosComplement.ino, along the lines of the code below that uses the assembly language instructions to determine the negative of the value variable without using the neg instruction. Display the result to confirm.

4. The neg instruction only operates on a single register (8-bit). Develop the sketch NegativeInt.ino that employs assembly language instructions to determine the negative of a global uint16_t (exactly 16 bits). Display the results to confirm with the BIN modifier.

9. Swapping 2. Declare and initialize a global variable of type uint8_t to 0xF0. Implement assembly language code to interchange the high and low nibbles before assigning the new value back into the global variable. Display the results to confirm.

8. Swapping 1. Declare and initialize two global variables to different values. Implement assembly language instructions to first, load the value into registers, and then interchange the values of the registers, then store the new values back into the global variables. Display the results to confirm.

9 [1718]. POV. The concept of a packed BCD numeric representation of a 2-digit decimal number involves interpreting each nibble of a byte as a 4-bit binary equivalent of a decimal digit. As such, bytes can only store values from 00 to 99 inclusive, with the latter being defined as 1001 1001. The packed BCD encoding of a 16-bit binary number would require 5 nibbles (3 bytes). The value 65535 would be stored as (LSB first),

9 [1718]. POV. The concept of a packed BCD numeric representation of a 2-digit decimal number involves interpreting each nibble of a byte as a 4-bit binary equivalent of a decimal digit. As such, bytes can only store values from 00 to 99 inclusive, with the latter being defined as 1001 1001. The packed BCD encoding of a 16-bit binary number would require 5 nibbles (3 bytes). The value 65535 would be stored as (LSB first),

| 0011 0101 |

|---|

| 0101 0101 |

| 0000 0110 |

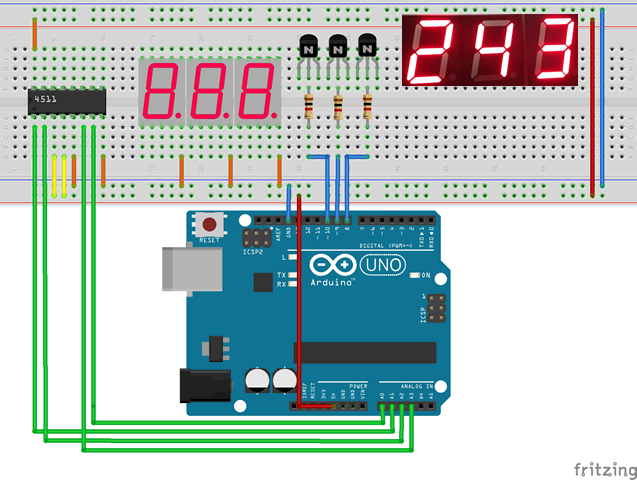

9 [1718]. Double Dabble POV. By now you've surely implemented the Double Dabble algorithm discussed weeks ago, in class. If you have, this challenge will be straightforward. If not, well....

For this practice challenge you are to present the result of the algorithm as a POV display on the three CC 7-segment displays provided. A single 4511 BCD-to-segment decoder will supply the segments as you continuously cycle through the three NPN's to provide the grounds in sequence.

Task.

8. [1718]. Hexadecimal Display.

Task.

At the end of the period, attach your your HexDisplay.asm file to an email to handin under the Subject Line: Hex Display

7. [1718] T. Morland's Shift Register-Bargraph Device. [cbi, sbi, clc, sec] From the timing diagram presented in the datasheet for your shift register you can review how the Data (SER), Clock (SRCLK), and Latch (RCLK) pins can be manipulated to feed your data bits into the internal storage flipflops of the IC before presenting (latching) them on the output pins.

7. [1718] T. Morland's Shift Register-Bargraph Device. [cbi, sbi, clc, sec] From the timing diagram presented in the datasheet for your shift register you can review how the Data (SER), Clock (SRCLK), and Latch (RCLK) pins can be manipulated to feed your data bits into the internal storage flipflops of the IC before presenting (latching) them on the output pins.

Just as J. Shaffer's handy Traffic Light PCB got us started with AVR assembly, we now turn to T. Morland's compact Shift Register-Bargraph PCB to explore low-level shift out assembly code.

Task.

7. Bit-Shifting (lsl, lsr, rol, ror, asr, lsr). Examine, and be able to explain the difference between of each of these six bit-shifting functions. Identify which ones can be considered 'destructive' in that the contents of the register they operate on is permanently altered?

6. Branching. The Program Counter, PC, is a two-byte register that always holds the address of the next instruction to be executed. Normally, after an instruction has been fetched from Program Flash' and placed into the Instruction Decoder, the Program Counter is incremented by 1, as in PC←PC+1. However, there are 20 branch instructions that cause the Program Counter to increase by a value other than 1, as in PC←PC+k. Each of the four-letter mnemonics for these instruction begin with the letters BR. Look them over and try to remember their unique purpose.

5. [17/18] Bargraph Flasher 10. Within the BIT and BIT-TEST Instruction group you'll find the highly useful rol and ror commands. Emlpoy one of them in your modification of the previous exercise to include all 10 LEDs in the bargraph. Save the sketch as BargraphFlasher10.ino.

5. [17/18] Bargraph Flasher 10. Within the BIT and BIT-TEST Instruction group you'll find the highly useful rol and ror commands. Emlpoy one of them in your modification of the previous exercise to include all 10 LEDs in the bargraph. Save the sketch as BargraphFlasher10.ino.

4. Bargraph Flasher 8 (ser, com). You're aware that sbi and cbi are convenient for setting and clearing individual bits in an I/O register. The ser instruction can be thought of as the complement of the clr instruciton in that it sets ALL bits in a GP register. Alternatively, to set multiple bits in an I/O register, the out instruction is used. All bits in a register can be inverted through the use of the com instruction.

4. Bargraph Flasher 8 (ser, com). You're aware that sbi and cbi are convenient for setting and clearing individual bits in an I/O register. The ser instruction can be thought of as the complement of the clr instruciton in that it sets ALL bits in a GP register. Alternatively, to set multiple bits in an I/O register, the out instruction is used. All bits in a register can be inverted through the use of the com instruction.

Task.

1. Wire the rightmost 8 LEDs of your bargraph to the PORTD pins on your Arduino.

2. Develop assembly language instructions within a sketch called BargraphFlasher8.ino that results in the effect displayed in the adjacent animation.

![]() 9. Analog-to-Digital (ADC) Converter (Peripheral). Chapter 24 of the ATmega328 datasheet discusses the Analog-to-Digital Converter. You should keep this handy for reference. MaxEmbedded provides a terrific primer on the ADC concept and register set for this stage. An excerpt appears below. We'll go through it together in class.

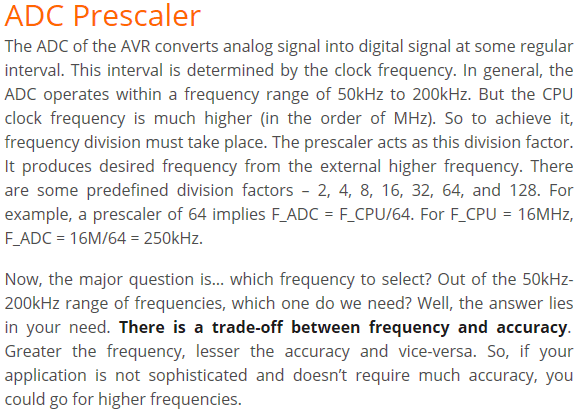

9. Analog-to-Digital (ADC) Converter (Peripheral). Chapter 24 of the ATmega328 datasheet discusses the Analog-to-Digital Converter. You should keep this handy for reference. MaxEmbedded provides a terrific primer on the ADC concept and register set for this stage. An excerpt appears below. We'll go through it together in class.

|

|

I have assembled a summary of the applicable ADC Registers (below) from Chapter 24 of the ATmega328P datasheet. After reviewing the recommended ADC example, implement the code necessary to have your pot, acting as a voltage divider, control the speed of your fan by reading the sweep leg (C) on Analog pin 0. Upload your code and test. The fan's speed should be responsive to your turning of the pot.

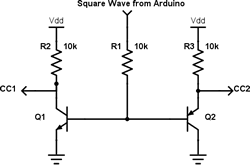

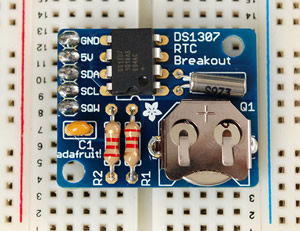

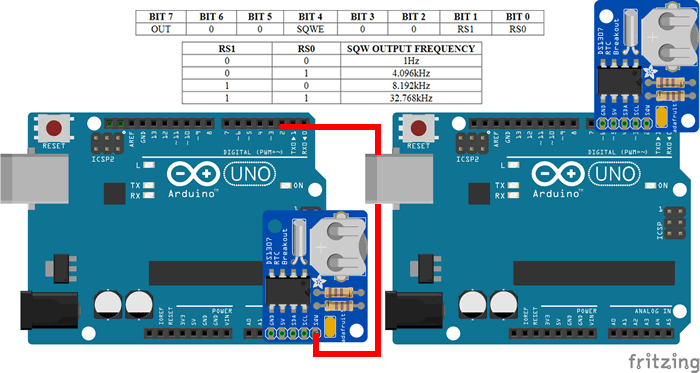

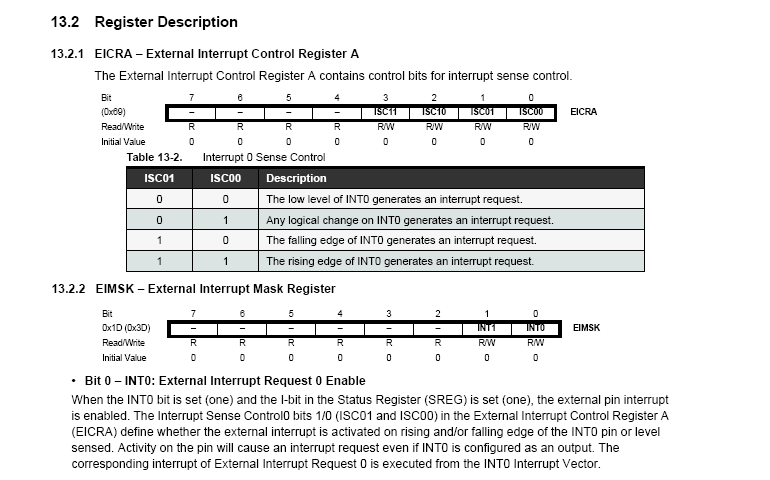

8. External Interrupts. Pin 7 of the I2C DS1307 RTC, labeled SQW/OUT, provides a configurable square wave, the frequency of which is scaled from its 32.768kHz crystal. Here's an excerpt from page 6 of the datasheet, as well as flag details of its Control Register,

Square Wave/Output Driver. When enabled, the SQWE bit set to 1, the SQW/OUT pin outputs one of four square-wave frequencies (1Hz, 4kHz, 8kHz, 32kHz). The SQW/OUT pin is open drain and requires an external pullup resistor. SQW/OUT operates with either VCC or VBAT applied. The pull up voltage can be up to 5.5V regardless of the voltage on VCC. If not used, this pin can be left floating.

|

|

The square wave from IC pin 7, is conveniently presented at the end of a 5-pin male header of Adafruit's breakout board. (This device would have made for a fantastic ACES Appliance but Adafruit thought of it first). E. McAuliffe (ACES '18) provides us with a trace of the 1 Hz signal from our scope above, right (click to enlarge). This exercise will introduce you a superior way to ensure your assembly code applications remain scheduled without wasting clock cycles as we have typically done through the use of an iterative delay function.

Task. (Instructions: cli, sei, reti).

7. BlinkSafe. We're now ready to take on the incredibly challenging (and hugely advantageous) study of AVR assembly language programming in Atmel Studio 7.

Task.

6. ExploreBits: Exploring the AVR 8-bit RISC (lds, sts, tst, and, or, brne, sbrc, sbrs, inc). A good way to explore the breadth of the AVR's Instruction Set is with some bit-manipulation algorithms.

Create the project ExploreBits with a minimal ExploreBits.ino driver file consisting only of the global variable value of type int8_t initialized to any value you like. Add a C loop() function with empty body (we will not be using the loop() function for the time being but main.cpp expects it to be present). Leave your bicolor LED in PortC from the previous exercise.

6. ExploreBits: Exploring the AVR 8-bit RISC (lds, sts, tst, and, or, brne, sbrc, sbrs, inc). A good way to explore the breadth of the AVR's Instruction Set is with some bit-manipulation algorithms.

Create the project ExploreBits with a minimal ExploreBits.ino driver file consisting only of the global variable value of type int8_t initialized to any value you like. Add a C loop() function with empty body (we will not be using the loop() function for the time being but main.cpp expects it to be present). Leave your bicolor LED in PortC from the previous exercise.

For each of below, if the assertion is true, your LED should be green, otherwise it should display red. Implement functions for each assertion and call it from your setup function. Your strategy can be destructive in that the value in r16 need not be preserved. Be sure to comment your code fully (comment the previous one out as your move through the exercises).

![]() 4. BicolorBlink (com). Place a bicolor LED in PortC. PortC is typically reserved for ADC support but let's give it a digital treatment in this brief study.

Create the standalone assembly project BicolorBlink, placing your entire code within BicoloBlink.S. Review and make use of the One's Complement AVR Instruction (com) in this exercise to have the device flash between red and green with a period of your choosing.

4. BicolorBlink (com). Place a bicolor LED in PortC. PortC is typically reserved for ADC support but let's give it a digital treatment in this brief study.

Create the standalone assembly project BicolorBlink, placing your entire code within BicoloBlink.S. Review and make use of the One's Complement AVR Instruction (com) in this exercise to have the device flash between red and green with a period of your choosing.

3. RGBLED. Place your CC RGBLED into your Arduino pins D6:3 (PD6:3), with the ground pin in D4.

3. RGBLED. Place your CC RGBLED into your Arduino pins D6:3 (PD6:3), with the ground pin in D4.

2. Traffic Light (clr, lsl, rcall, lsr, rjmp). Place your Schaffer's Traffic Light into your Arduino pins D11:8 (PB3:0), with the ground pin in D8. Develop inline assembly code (using only a single asm() block within each of the setup() and loop() functions) that runs the device continously with 3s-1s-3s delays between Green-Yellow-Red LEDs. Save the sketch as TrafficLightBasic.ino.

2. Traffic Light (clr, lsl, rcall, lsr, rjmp). Place your Schaffer's Traffic Light into your Arduino pins D11:8 (PB3:0), with the ground pin in D8. Develop inline assembly code (using only a single asm() block within each of the setup() and loop() functions) that runs the device continously with 3s-1s-3s delays between Green-Yellow-Red LEDs. Save the sketch as TrafficLightBasic.ino.

1. Blink (ldi, out,eor). Using inline assembly, rewrite the Blink Sketch. Use the Arduino C delay() function.