| 2014-2015 TEI4M ACES: The RSGC 50th Anniversary Clock |

In recognition of RSGC's Golden Jubilee, the 2014-2015 TEI4M ACES engaged in an ambitious undertaking to design and engineer a limited number of 50th Anniversary Clocks. Here's the result (click to enlarge). Read below to get a sense of the process :)

After a year of R&D, the result was beyond what was imagined. The final design centered on an inward-facing strip of 60 RGB LEDs (NeoPixels) that can be individually addressed and tuned to any desired colour combination. The greatest challenge was the interior presentation display module to contain and present the optical output. What emerged after months of discussion and debate was a two-piece, fingered-jointed, interior ring that receives the LED illumination to highlight the hour and minute data. A custom-designed and fabricated circuit board, carrying the ATmega328P, ChronoDot, user controls and other electronics, sits in a well within the base. RSGC's 50th Anniversary Crest in engraved to the right of the display.

After a year of R&D, the result was beyond what was imagined. The final design centered on an inward-facing strip of 60 RGB LEDs (NeoPixels) that can be individually addressed and tuned to any desired colour combination. The greatest challenge was the interior presentation display module to contain and present the optical output. What emerged after months of discussion and debate was a two-piece, fingered-jointed, interior ring that receives the LED illumination to highlight the hour and minute data. A custom-designed and fabricated circuit board, carrying the ATmega328P, ChronoDot, user controls and other electronics, sits in a well within the base. RSGC's 50th Anniversary Crest in engraved to the right of the display.

Ten units were produced, the first of which was presented to our Headmaster. The one-of-a-kind project stands as a testament to the collective talent, perseverance, and collaborative effort of committed Georgians and their extraordinary partner, Mr. P. Elia. What appears below is brief overview of a few of the stages that were engaged in the process.

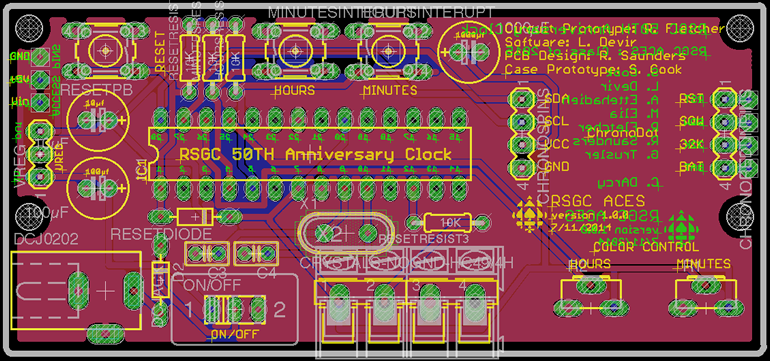

In keeping with the 'from the ground up' objective of this project, we needed a custom circuit board to drive the system. With plenty of EAGLE experience in creating DIY circuit boards a year earlier in Grade 11, and a couple of successful board designs outsourced to China earlier this year, we were ready to undertake this critical step.

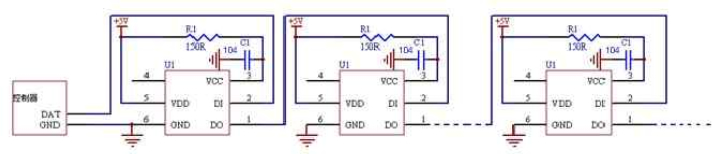

Our requirements called for an Arduino-like microprocessor system based on the mega328P (with which we were familiar) to manage the peripherals that included a ChronoDot, a NeoPixel strip, momentary buttons for hour-minute adjustment and hour-minute colour-control potentiometers for decor-matching capability, among other features. Once the through-hole schematic was developed, the board file layout completed and the Gerber files prepared, the files were sent to China. All we could do was wait...

When the boards came back some stressful soldering sessions were undertaken to poplulate the board, prior to testing... As it turned out, the boards worked to perfection! The successful outcome of our combined efforts appears in the photo to the right (click to enlarge). As can be seen in the photo at the top of the page, the populated boards sit in a recessed well in the acrylic base, with the three NeoPixel control wires inserted up through a channel to the ring in the vertical panel. Here's a video of the board being tested:

https://www.youtube.com/watch?v=eaXaLS76d9c&feature=youtu.be

| Initial Research: Spring 2014.

Of the many clock options, the Once a successful KickStarter project, the ClockOS has a permanent home. In addition to the ClockOS Manual, the following pdfs provide additional details of the design, Here's another adaptation of the open source ClockOS project. |

|

2014 Planning/Brainstorming Sessions

|

2014 Investigations

L Clock: Research and References

LED Driver Considerations: slyt084.pdf

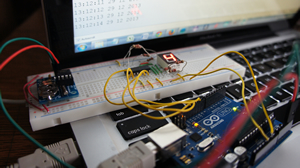

December 29 2013. First attempt at reading the output of DS1307 RTC from an Adafruit Breakout board. Adafruit Tutorial: DS1307 Real Time Clock Breakout Board Kit |

|

|---|

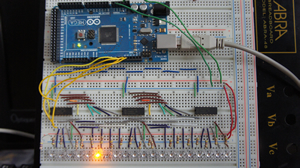

| January 1, 2014. Example of the use of HEF4794 LED Drivers to control a sequence of LEDs through sinking (rather than sourcing) current. This concept could be used to advance the hour, minute and second LED strings using input from the DS1307 or Chronodot.

|

|

October 2014. Ove the Thanksgiving weekend, S. Cook developed a sample case made of pine that reflected the group's design decisions.

|

|

December 2014. Over the Christmas holiday, a cabinetmaker was commissioned to develop a prototype base on the previous design made from striped Canadian maple. Time delays and cost combined to eliminate this housing design as a viable option.

|

|